Please contact us to collaborate on your engineering and development projects.

We are at the forefront of research in composite materials.

We adapt our solutions to the specific needs of each client.

Our team of experts has mastered the latest technologies.

We develop environmentally friendly composites.

We guarantee quality and timely delivery.

Our primary concern has always been to perfect our expertise. Over the years, we have refined our processes and methods and introduced a multitude of innovations.

Know-how is not merely a skill; it is a tradition of excellence that we are proud to uphold.

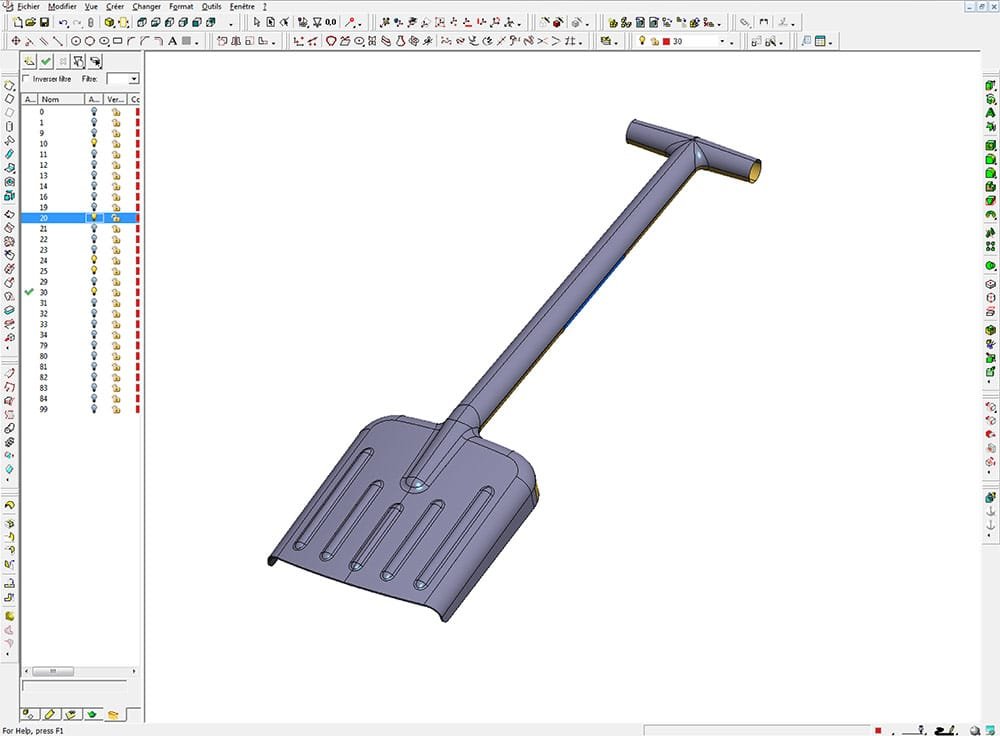

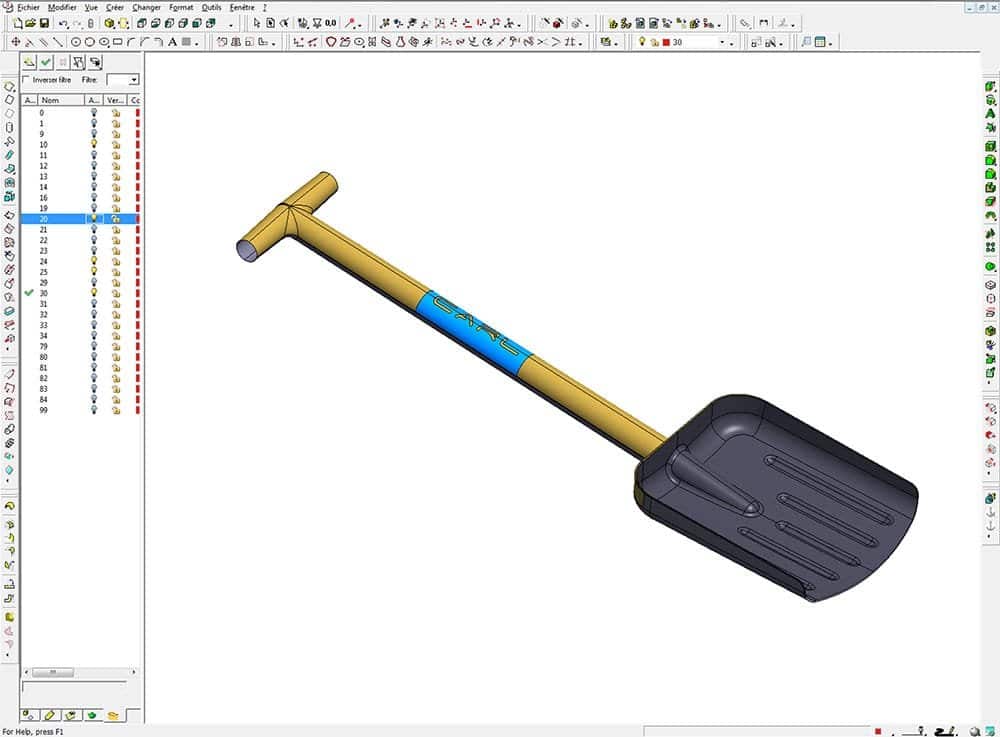

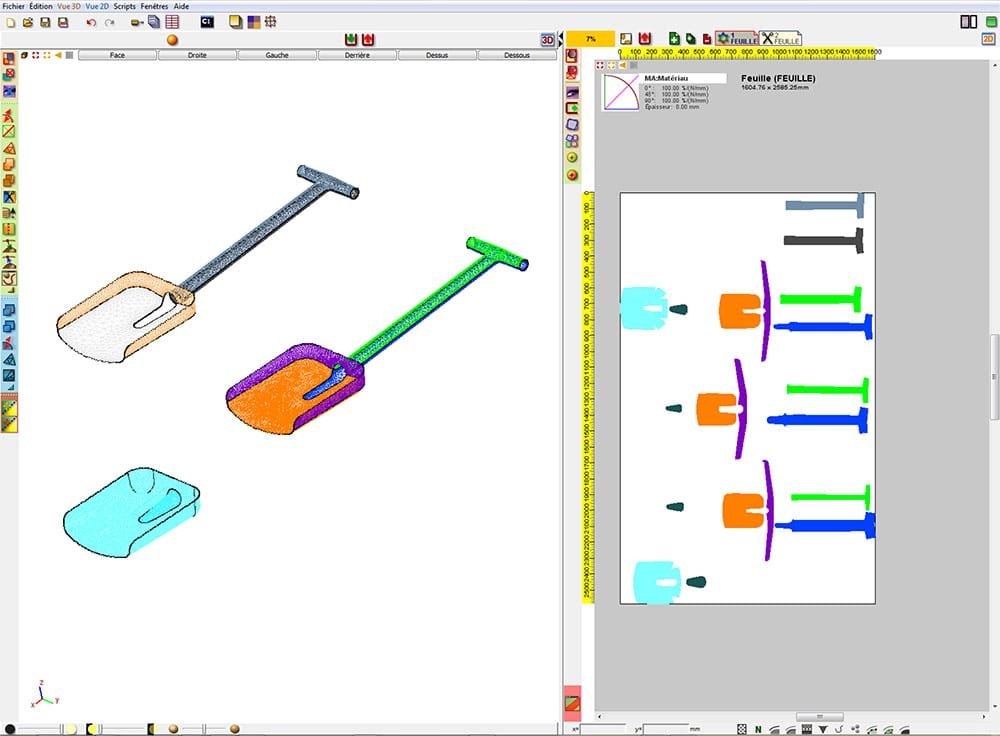

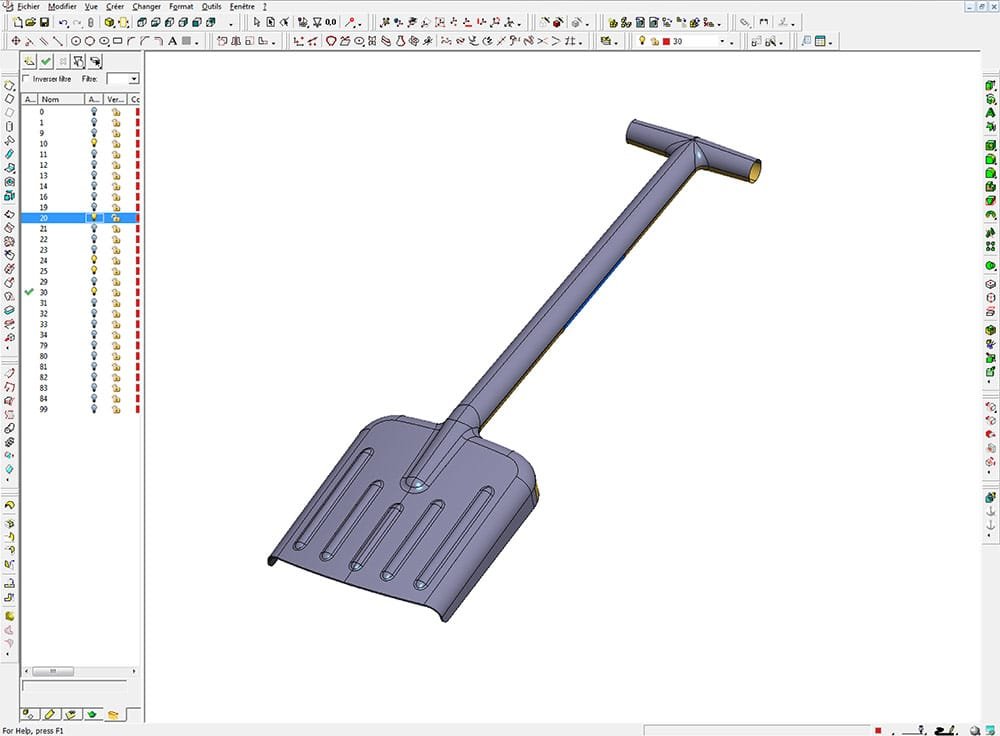

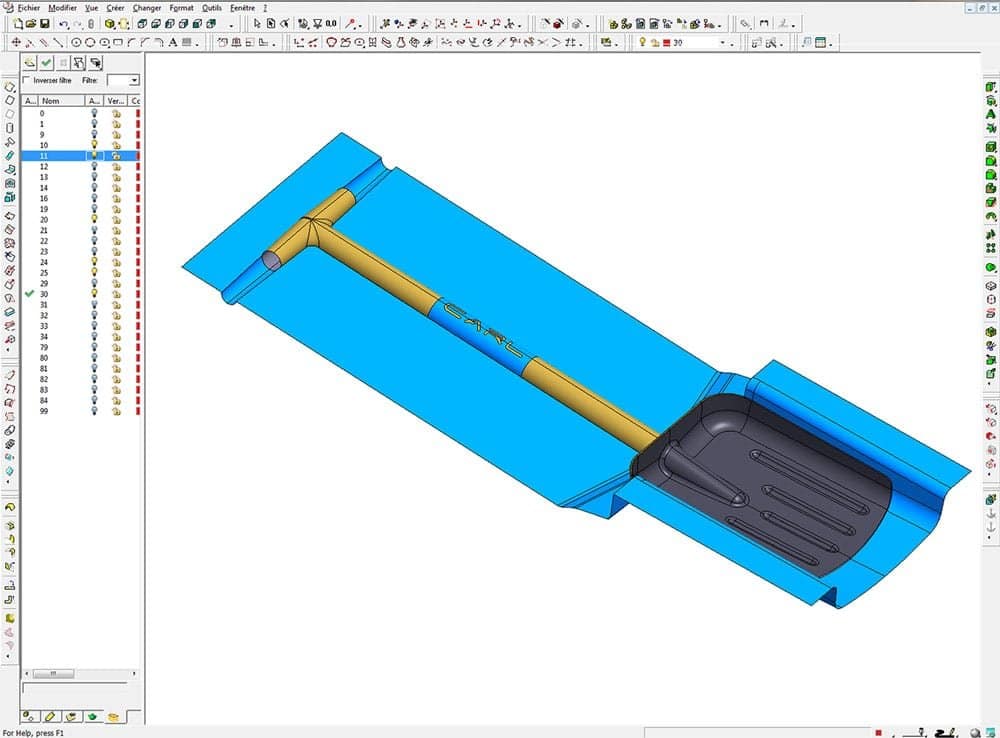

Since our establishment in 2004, we have machined our models in-house, which is why we have acquired 5-axis machining centers qualified by the aerospace industry. Alongside our modeling activities, we have developed a business in manufacturing composite material tools for the aerospace industry.

Today, tooling intended for clients in the automotive industry is designed and produced according to aerospace standards.

For over 20 years, we have been working on the transformation of composite materials through autoclave polymerization.

This production is strictly regulated by ISO 9001 and IATF standards.

Each production has its own identification, allowing for 100% traceability, and every operator participates in this traceability.

Our team of engineers, researchers, and technicians works tirelessly to improve productivity, quality, and repeatability.

Over the past ten years, in addition to our focus on producing better and more, we have also prioritized producing “cleaner” by consuming fewer materials, consumables, and energy.

NEED INFORMATION?

By submitting your request via our form